finally was able to get some turning going on last night

Nailed all my measurements

Next monday I should be able to start cutting, our instructor recommended this video for a refresher over the math from last week for the future

The following users say thank you to K for this useful post:

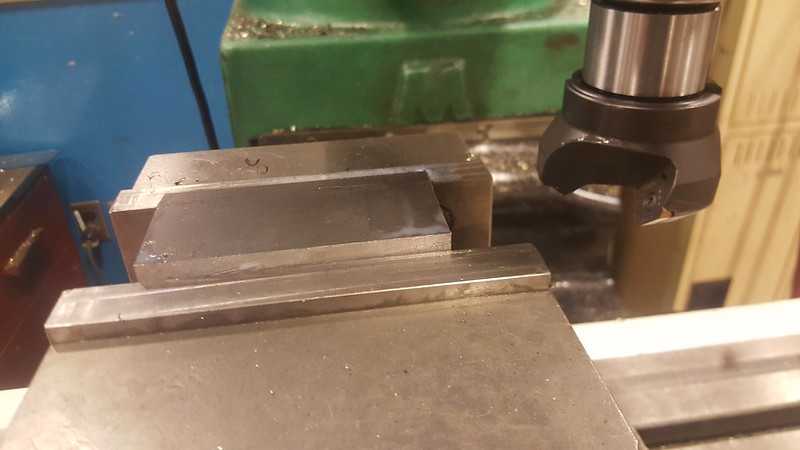

icanreachitso finished up the class last night, since I had completed my threading project last week the instructor said we could do whatever we wanted, so I figured I would get back to my die project. I cut a piece of A36 at home and brought it in with me. The school had a carbide face mill that I used.

Cut through that hard outer scaling like butter, so I ordered one this morning.

I faced up the rest of the sides and had a width of 1.960, so I found my outer edge.

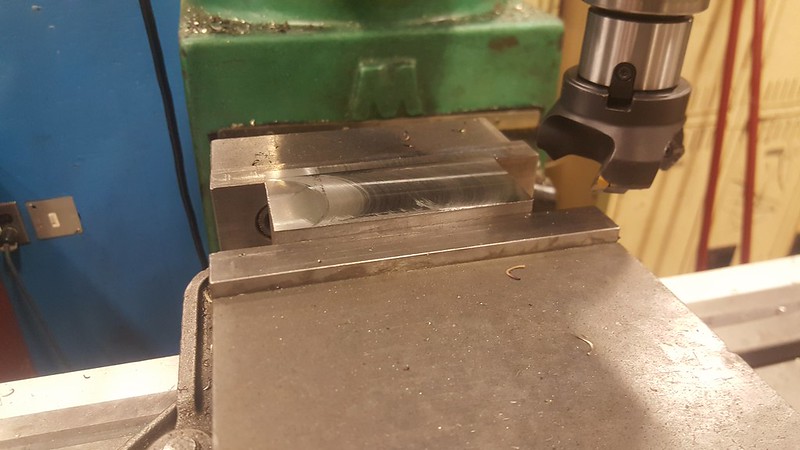

And milled out the middle

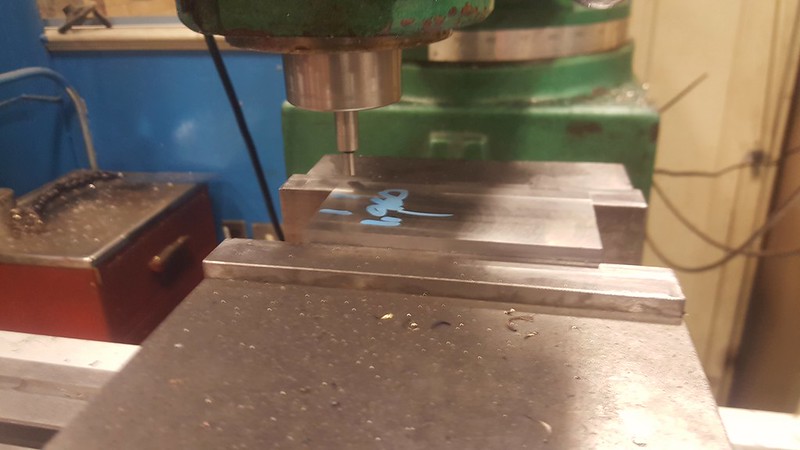

I only had about 45 minutes left in class so instead of just getting the other side started, I cleaned up and thanked the instructor and went home. I'm going to finish the other side, cut out the ends for mounting tabs, cut it down the middle with my bandsaw and I will have my die's pretty much done. Much easier this way than the way I was doing it before.

Most Users Ever Online: 698

Currently Online:

17 Guest(s)

Currently Browsing this Page:

1 Guest(s)

Top Posters:

easytapper: 2149

DangerDuke: 2030

groinkick: 1667

PorkChopsMmm: 1515

Gravel Road: 1455

Newest Members:

alexandrahic

phillippcarolan

lucybrunker162

ricoavila62

joe4257694859449

Forum Stats:

Groups: 1

Forums: 12

Topics: 11478

Posts: 58673

Member Stats:

Guest Posters: 2

Members: 3496

Moderators: 0

Admins: 1

Administrators: K

Register

Register Log In

Log In Home

Home

Offline

Offline