19 Feb ’12

Offline

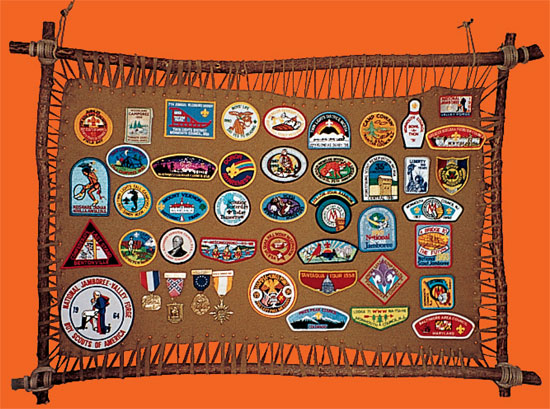

OfflineOk, so I saw this cool project for creating a "stretched hide display". I thought it would be great for all my son's scouting patches. For the most part, I plan to follow the instructions. The one step I wanted to skip was screwing the pieces of wood together. I'm thinking of using rawhide, instead. I know if rawhide is wet, it will shrink and harden when it dries. So, with that in mind, I assume I wet the rawhide, then do my lashings?? Or should I do the lashings, and then wet the rawhide?

19 Feb ’12

Offline

OfflineKVR said

let's try this again, @spotted-horses and @hessian would be the ones knowledgeable on leather work, sounds like a sweet project

I've done a little research online, and it seems like you want the rawhide wet before lashing, but not too wet, just damp. If it's too wet, then it will swell and then be loose after if dries out.

21 Feb ’12

Offline

OfflineI have a couple of pieces stretched right now for kukri. I owe a couple friends hand made blades for their adventures.

Mostly do wetting, stretching and then heating to gain strength and form. If I was going to do a lashing project I would do the lashing holes first and form them with some heat before giving it a good stretch as they will probably split otherwise. Or use rings pressed into the lashing holes till I have most the stretch done.

I use a wooden form of the blade shape to stretch and form it and heat/clamp it for the old man who does the actual sewing part.

Try and get the hide from a tanner who does salt tanning as it will be better for your applications I think. Or just cut out the size you need from a blacksmith apron?

Cool project, Easy.

Hessian said

I have a couple of pieces stretched right now for kukri. I owe a couple friends hand made blades for their adventures.Mostly do wetting, stretching and then heating to gain strength and form. If I was going to do a lashing project I would do the lashing holes first and form them with some heat before giving it a good stretch as they will probably split otherwise. Or use rings pressed into the lashing holes till I have most the stretch done.

I use a wooden form of the blade shape to stretch and form it and heat/clamp it for the old man who does the actual sewing part.

Try and get the hide from a tanner who does salt tanning as it will be better for your applications I think. Or just cut out the size you need from a blacksmith apron?

Cool project, Easy.

Agree. Wet stretch then heat. The heat part is important.

Hessian, what is kukri?

Be RADICAL Grow Food

Most Users Ever Online: 698

Currently Online:

18 Guest(s)

Currently Browsing this Page:

1 Guest(s)

Top Posters:

easytapper: 2149

DangerDuke: 2030

groinkick: 1667

PorkChopsMmm: 1515

Gravel Road: 1455

Newest Members:

Forum Stats:

Groups: 1

Forums: 12

Topics: 11482

Posts: 58640

Member Stats:

Guest Posters: 2

Members: 19842

Moderators: 0

Admins: 1

Administrators: K

Log In

Log In Home

Home