DIY 55 Gallon Aquaponics Project

DIY 55 Gallon Aquaponics Project Anyone started 3d printing stuff yet?

Anyone started 3d printing stuff yet? Food trailer power source

Food trailer power source Tractor thread

Tractor thread27 Aug ’14

Offline

OfflineHaha pretty awesome for spot cooling but yeah, gotta look at the power used on the whole. I can't seem to remember (or find on google) which president it was but that was his idea for fixing global warming: drop a giant chunk of ice in the north pole and we'll be set for another 50 years. Nobody thought about the heat produced or the energy consumed during the production of that iceberg.

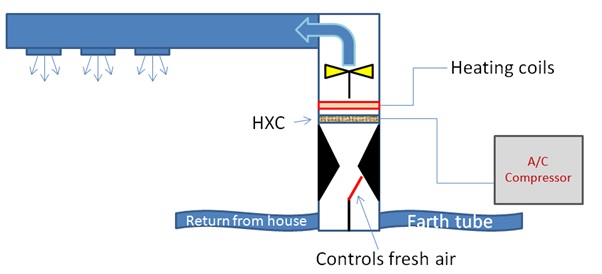

Sounds like my best option would be earth tubes at said depth and then just having a simple damper for controlling the re-circulation vs fresh air mixture.

This provides for a system where the A/C can pick up the slack per say and also dehumidify. The damper would be set to a small arduino board that measures inlet temperatures from the house return, earth tube, and internal house temperatures. If the earth tube temperature is within a particular range then the damper can be set to pull up to 80% of the required CFM (the central air's fan rating) from the earth tube, maintaining 20% re-circulation. If the earth tube temperatures are too low or high (mid summer or winter) then the damper can be toggled (using a small servo motor) to allow up to 80% of the required CFM from the re-circulation side, thus maintaining the minimum 0.6 ACH per industry standards.

The black portions are just made of sheet metal for avoiding stagnation and optimizing the flow around the damper.

I am considering including a small Energy revovery ventilation device or an HRV running parallel to the unit and exiting where the earth tubes enter the unit. Because the house is old, and likely has plenty of leaks, this should control the pressure and minimize energy losses until I can get it sealed per Albinorhino's suggestion of using spray foam or blown in fiberglass.

19 Feb ’12

Offline

Offlineicanreachit said

Haha pretty awesome for spot cooling but yeah, gotta look at the power used on the whole. I can't seem to remember (or find on google) which president it was but that was his idea for fixing global warming: drop a giant chunk of ice in the north pole and we'll be set for another 50 years. Nobody thought about the heat produced or the energy consumed during the production of that iceberg.Sounds like my best option would be earth tubes at said depth and then just having a simple damper for controlling the re-circulation vs fresh air mixture.

This provides for a system where the A/C can pick up the slack per say and also dehumidify. The damper would be set to a small arduino board that measures inlet temperatures from the house return, earth tube, and internal house temperatures. If the earth tube temperature is within a particular range then the damper can be set to pull up to 80% of the required CFM (the central air's fan rating) from the earth tube, maintaining 20% re-circulation. If the earth tube temperatures are too low or high (mid summer or winter) then the damper can be toggled (using a small servo motor) to allow up to 80% of the required CFM from the re-circulation side, thus maintaining the minimum 0.6 ACH per industry standards.

The black portions are just made of sheet metal for avoiding stagnation and optimizing the flow around the damper.

I am considering including a small Energy revovery ventilation device or an HRV running parallel to the unit and exiting where the earth tubes enter the unit. Because the house is old, and likely has plenty of leaks, this should control the pressure and minimize energy losses until I can get it sealed per Albinorhino's suggestion of using spray foam or blown in fiberglass.

That looks very nice! Keep in mind some form of humidity control for your earth tube air. The tube temp might look good but humidity might be high making the house feel hotter.

This is very similar to a Economiser system. An Economiser is installed on most rooftop package units on businesses that require cooling well into the colder months. Also called "free Cooling". Air conditioned air is usually around 50-55 degrees anyways. So if it is 55 outside the damper opens while also blocking the return air duct partially.

About the spray foam, I believe Dow chemical now sells project packs for DIY. They consist of 2 tanks (looks to be the size of freon or propane grill tanks), a spray nozzle and 2 pipe hoses. When the 2 chemicals in the tank mix at the tip it creates the foam. I want to say it was $600 bucks for a set-up to do 100 sq. ft. That price may of dropped now. Also in our area Isonene is really catching on and it seems every insulator is now offering it...the price has really come down a bunch on the commercial level.

Most Users Ever Online: 698

Currently Online:

47 Guest(s)

Currently Browsing this Page:

1 Guest(s)

Top Posters:

easytapper: 2149

DangerDuke: 2030

groinkick: 1667

PorkChopsMmm: 1515

Gravel Road: 1455

Newest Members:

Forum Stats:

Groups: 1

Forums: 12

Topics: 11482

Posts: 58640

Member Stats:

Guest Posters: 2

Members: 19842

Moderators: 0

Admins: 1

Administrators: K

Log In

Log In Home

Home