DIY 55 Gallon Aquaponics Project

DIY 55 Gallon Aquaponics Project Anyone started 3d printing stuff yet?

Anyone started 3d printing stuff yet? Food trailer power source

Food trailer power source Tractor thread

Tractor threadWell made some design changes, newsettler made a good point that the side pieces should be welded to the base and the sides of the square tubing to counteract upwards lift.

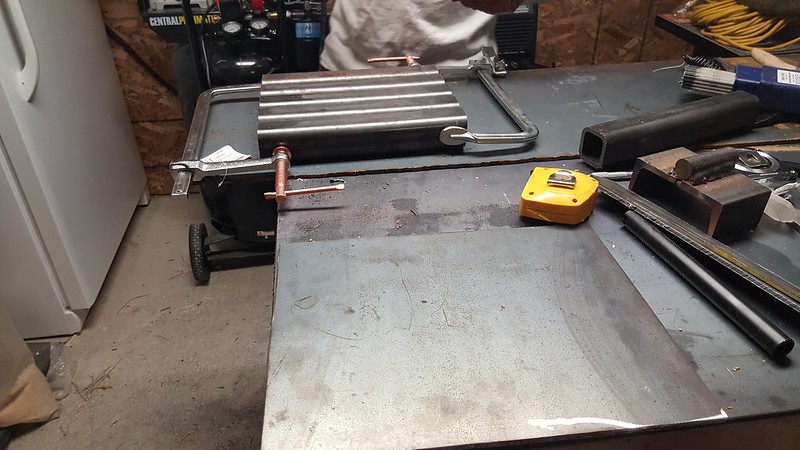

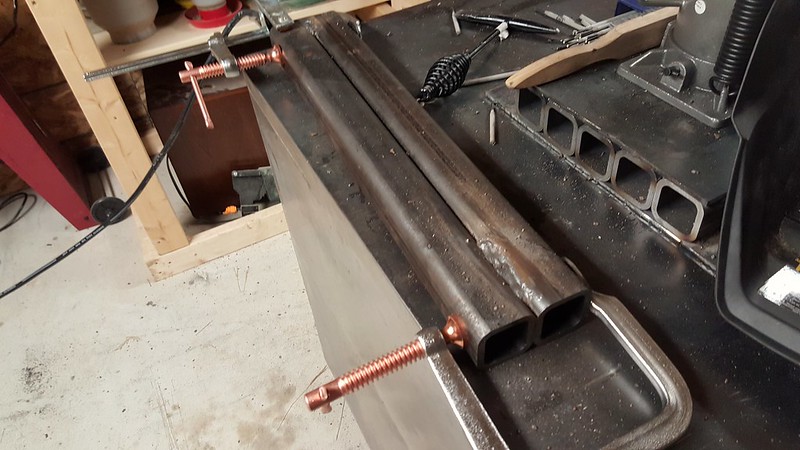

So we cut down some more plate as a base.

the plasma cutter works slick

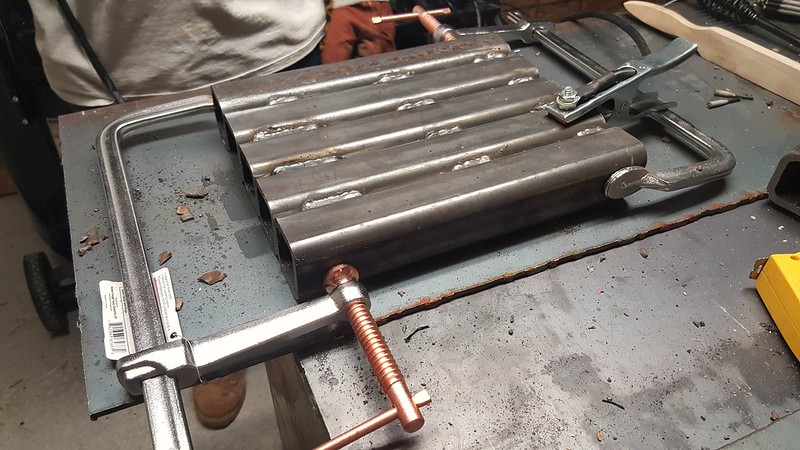

clamped together the base squares

and welded them together

one side done

flipped it over, welded the other side and centered it on the base

welded the two together

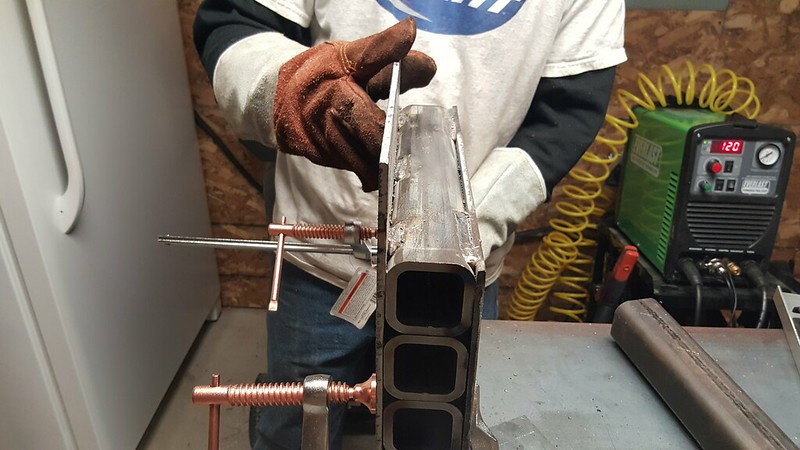

flipped it on it's side and welded the ends

welded on the top plate

should hold

Have to fab up the side pieces today

So I started messing with the jack to check out my heights to see what I want my top anvil to be at

Still not sure if I want a fixed top anvil or adjustable one but I picked up some cat 8 bolts just to be safe, I figured 22 inches will give me a good height whichever way I decide.

Newsettler was working so I said screw it, I'm welding this puppy up!

Holy crap that is horrible

So newsettler stopped back and showed me where I really screwed up, seems tack welding the corners first is ideal or else you get some heat bending.

Thank goodness I bought plenty of stock

So I tacked up a couple more pieces

Much better

So I have enough stock to cut 4 more pieces of height and should leave me enough for the anvils, going to try and weld up the other side today, if I screw that up then back to a single side arm design we go.

The following users say thank you to K for this useful post:

Gravel RoadSo I cut up the rest of the square stock

decided to clean up the mess I made and practice some

little bit better

not as bad as before, still have some work to do

Did get a chance to test the variable speed controller from harbor freight my wife picked up to see if my old table saw would work for a variable speed belt sander project this summer.

So I realized we had made a mistake, we had bought 1/4 inch plate for the base and used the 3/16ths from the table top instead

so I grinded through the welds

and cleaned up the base pipes

I marked up my width on the 1/4 inch

And offset my guide by an inch for the plasma cutter

only took a couple minutes and I cleaned up the edges

cleaned up the side arms, we decided to go with a single arm design

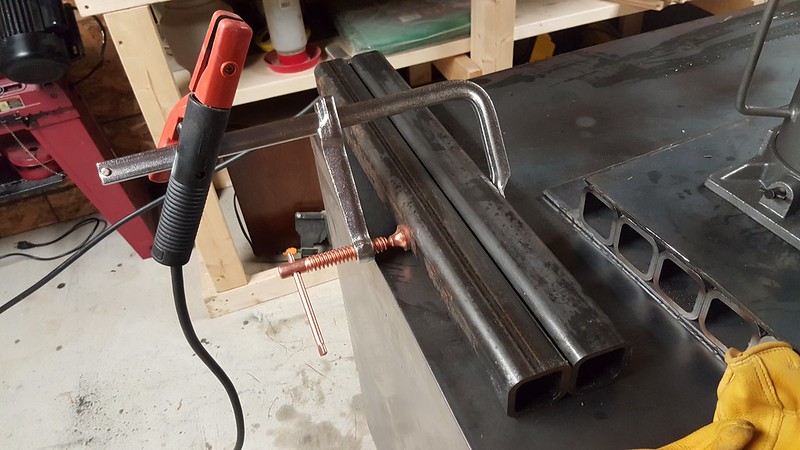

Mocked it up with some welding squares and spot welded

flipped it on it's side and completed the weld

now to do the other side

Drilled out some holes for a die holder, not sure if this is the route I still want to go with

Starting to look like something, need to weld the anvils in place yet

some great videos on Tom Joyce, that bastimal fountain is sweet

The following users say thank you to K for this useful post:

Hessiantime to start making some dies

So I picked up my piece of metal, crazy that this weighs over 100 pounds

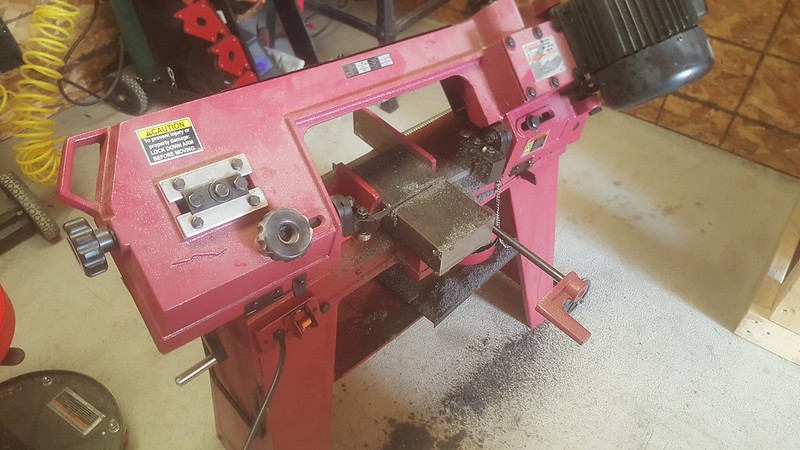

I needed to break it down some so I threw it in the bandsaw

and cut it down again

and again

those 4 inch blocks are 8 pounds each

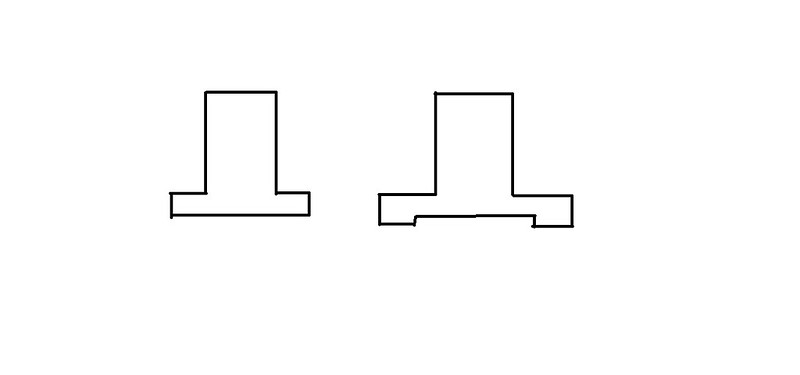

I am going to mill two different prototypes and test them, this is not to scale

one that can be retained by bolts on the left, or one that can be retained by being bolted down into the top or the face of the anvil

Need to calculate my feeds and speeds and I'm going to go and try to knock some out.

The following users say thank you to K for this useful post:

HessianMost Users Ever Online: 698

Currently Online:

152 Guest(s)

Currently Browsing this Page:

1 Guest(s)

Top Posters:

easytapper: 2149

DangerDuke: 2030

groinkick: 1667

PorkChopsMmm: 1515

Gravel Road: 1455

Newest Members:

Forum Stats:

Groups: 1

Forums: 12

Topics: 11482

Posts: 58640

Member Stats:

Guest Posters: 2

Members: 19842

Moderators: 0

Admins: 1

Administrators: K

Log In

Log In Home

Home

Offline

Offline