27 Aug ’14

Offline

OfflineWhat spacing do you use for form supports?

Do you set the lag screws in the edge of the slab before or after it has cured?

Do you do anything special while it is curing to keep it from cracking? In Texas i usually see wet cloths continuously sprayed to ensure that it dries from the inside out.

Does it always look so easy or just after your fourth or fifth?

icanreachit said

What spacing do you use for form supports?Do you set the lag screws in the edge of the slab before or after it has cured?

Do you do anything special while it is curing to keep it from cracking? In Texas i usually see wet cloths continuously sprayed to ensure that it dries from the inside out.

Does it always look so easy or just after your fourth or fifth?

we use metal grade stakes every three feet, those are what is outside the forms, wood works just as well

when I built my house, I just used pointed 2x4's

anchor bolts can be popped in right after the first float

water curing is important to prevent cracking and hazing, especially in hot sunny conditions, you can drape with wet cloth and/or plastic. You basically want to keep the concrete from drying too fast. Since we poured in the late afternoon, were in the shade and it was down around 60 degrees I didn't worry about it.

Pouring is easy, it's the finish that is really the hard part, it's very easy to mess up while floating. The way I look at it though is that any imperfections give the buildings charm and reminds me of the process when I see them in the future.

I actually wanted to do a broom finish but it was getting late and we ran out of daylight

So the forms got ripped off and a chalkline was snapped on the slab to show where the plates were going

to set the plate lay down some sill seal and set the PT board over the anchor bolts and smack the back of the board with a hammer above each one, this will leave an imprint where the bolts are so that you can just drill them out and set the board down onto the them, you may need to maneuver the board to line up properly.

You may want to ramset the boards down as well to help straighten out any curves that boards may have.

Hey, I got a doorway!

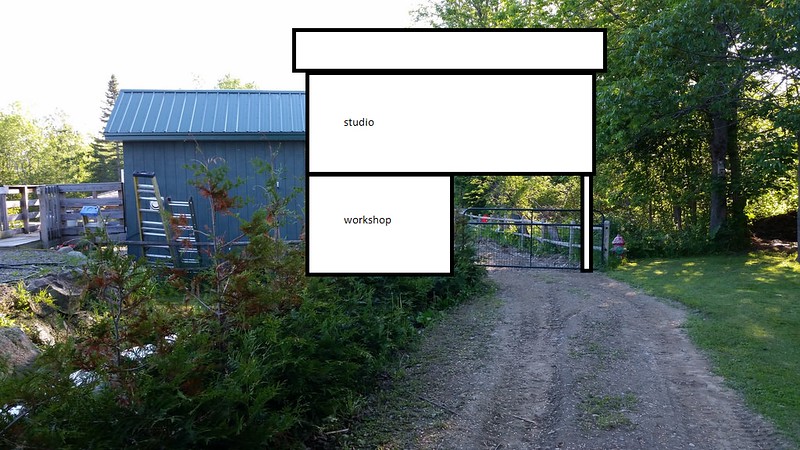

My workshop is enclosed, it is 12x20

Started cutting some studs

And built up the L-corners

started laying out the walls

framing out the doorway

Needed to cut some more off the back of the existing cabin

workshop framed

well look at those big fellas

the 6x6's are going to be used to support the cantilevered section of the second

called it a day and we will be starting back on monday, should pretty much have the second story framed that day, roof sheathing might be iffy. It's getting there.

Most Users Ever Online: 698

Currently Online:

37 Guest(s)

Currently Browsing this Page:

2 Guest(s)

Top Posters:

easytapper: 2149

DangerDuke: 2030

groinkick: 1667

PorkChopsMmm: 1515

Gravel Road: 1455

Newest Members:

Forum Stats:

Groups: 1

Forums: 12

Topics: 11482

Posts: 58640

Member Stats:

Guest Posters: 2

Members: 19842

Moderators: 0

Admins: 1

Administrators: K

Log In

Log In Home

Home