DIY 55 Gallon Aquaponics Project

DIY 55 Gallon Aquaponics Project Anyone started 3d printing stuff yet?

Anyone started 3d printing stuff yet? Food trailer power source

Food trailer power source Tractor thread

Tractor thread5 Mar ’12

Offline

OfflineI was going to say you could start making suppressors. People sell lots of parts now online that with some drilling and cutting make some simple suppressors. I put in for 4 NFA stamps a few months ago to build an SBR and 3 more suppressors (another 22LR, 9mm, and 308). I should have approval in the new few weeks and then I will order my parts online. You could make similar parts and sell them. I'm not sure how many you could crank out with such a set up but if you did some custom work it would be a nice way to make a side income.

well upgraded to the elite, shipped out today will be here thursday

ordered a 4 inch I beam today, need to go pick it up in the morning

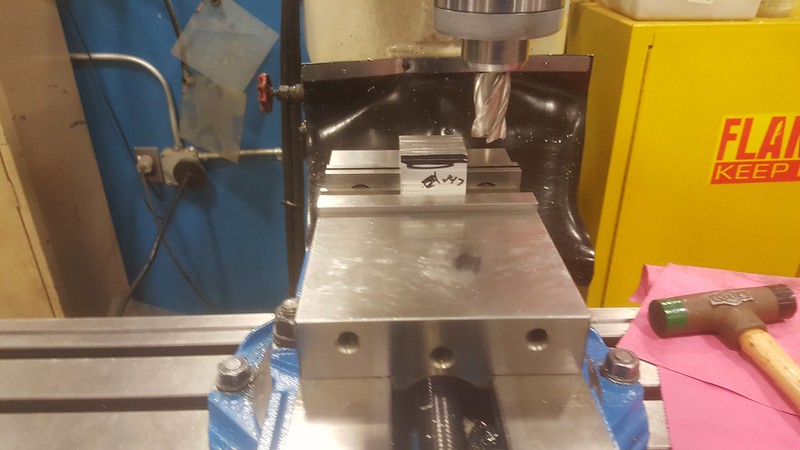

had class tonight, should finish up with the v-blocks next week and then we move to lathe work from the mills, I cheated and marked my piece with a sharpy, scored it with the calipers to get a rough estimate for cut and wrote on my piece my depth of cut. I was still off one thousandths

I think @pcso112 and I talked the instructor into doing a machining 2 course, they use to run one but stopped due to lack of interest, so that is pretty cool

6 Oct ’15

Offline

OfflineI think if you hang the beam with enough hangers it will handle a half ton...or pull your ceiling down.

A few thoughts (some may not apply/be relevant)

1) Do you really think you will actually lift 900#?

2) How are you going to suspend this from the Ceiling joists? Steel Brackets? Wooden blocking? Posts/A's? Chain?

-If I am right and you are suspending it from the joists I would build them up a lot. Sister them with Doug Fir, Construction adhesive & Nails/Spikes shot in from a Air Nailer (Full Heads-Not Clipped Heads...they generally have better sheer strength than screws...you could use carriage bolts too (would be a lot of them and pricey) I would use grade 8 bolts...If you really want to ensure all the strength in the world on your ceiling joists, then sister on full lengths of plate steel that is carriage bolted on, pricey though, normally for heavy headers in framing they sometimes sandwich plate steel in between a couple of 2 x's, it is pretty old school, but it a lot of old timers still do it...of course other is to put up an engineer LVL beam.

3) I would check a structure/engineering chart for your H or I beam and see what it is rated for on working load and dead load, a good chart would also tell you how often to support it (every 2 ft or 3 ft or whatever).

4) This kind of goes back to #3, is there any marking on the beam grade/rating? That will help a lot...type of steel, forging process, thickness of webs all go into it.

5) I know you got the beam...just another Idea...I was at HF today and they had a adjustable height manufacturing/material cart (at least that is what I am calling it) I just glanced at it...thought it had a 500# rating on it and it was like $190...it had like a 2x3 ft surface on it...that should roll pretty decently on the concrete floor?...a partial alternative?

Most Users Ever Online: 698

Currently Online:

69 Guest(s)

Top Posters:

easytapper: 2149

DangerDuke: 2030

groinkick: 1667

PorkChopsMmm: 1515

Gravel Road: 1455

Newest Members:

Forum Stats:

Groups: 1

Forums: 12

Topics: 11482

Posts: 58640

Member Stats:

Guest Posters: 2

Members: 19842

Moderators: 0

Admins: 1

Administrators: K

Log In

Log In Home

Home