27 Aug ’14

Offline

OfflineAlright, finally heard back: plans were rejected but the requested changes were minimal and I'm actually doing them as I type this.

While I'm waiting for beaurocracy, I'm doing as much work as I can so that I don't lose time. The AC has to be moved for the addition and instead of filing permitting papers, I'm just hiring someone to move the thing. I wasn't happy with the styrofoam coated with cement/epoxy that I picked up for $20 so I decided to salvage the old one.

I lifted it off of the old one so that I could pull it out and re-position the old pad:

Pulled out the old pad:

Re-positioned and leveled:

Then started to excavate to lower my costs for having someone else pour the slab. Anyone have recommendations on where to find people? Yelp hasn't been much help so I'm thinking of using Angie's list.

Most of the loamy soil will have to be removed so that crushed rock can be brought in. I'm also going to have them pour a short stem wall (curb) around two sides so that I can bury this addition as much as possible to help with thermal swing.

27 Aug ’14

Offline

OfflineThanks KVR! She's a corgi mix that we picked up on the streets of Chile. You'd never know until she stands up that she has any corgi and she only barks about once a month.

Submitted plans for final review today and wanted to mention that I'm adding the curb back to the design after reviewing that woodshop video that you sent. Protecting the thermal mass as best as possible and sinking it should help with the HVAC needs of the addition (which may or may not be tapped into the existing hvac).

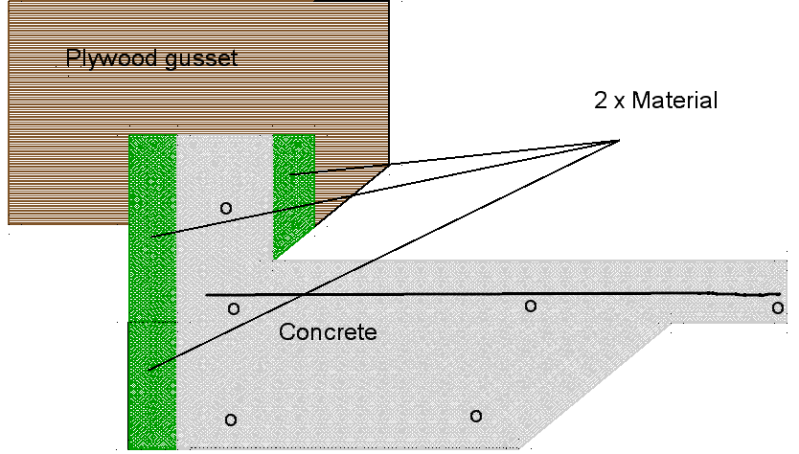

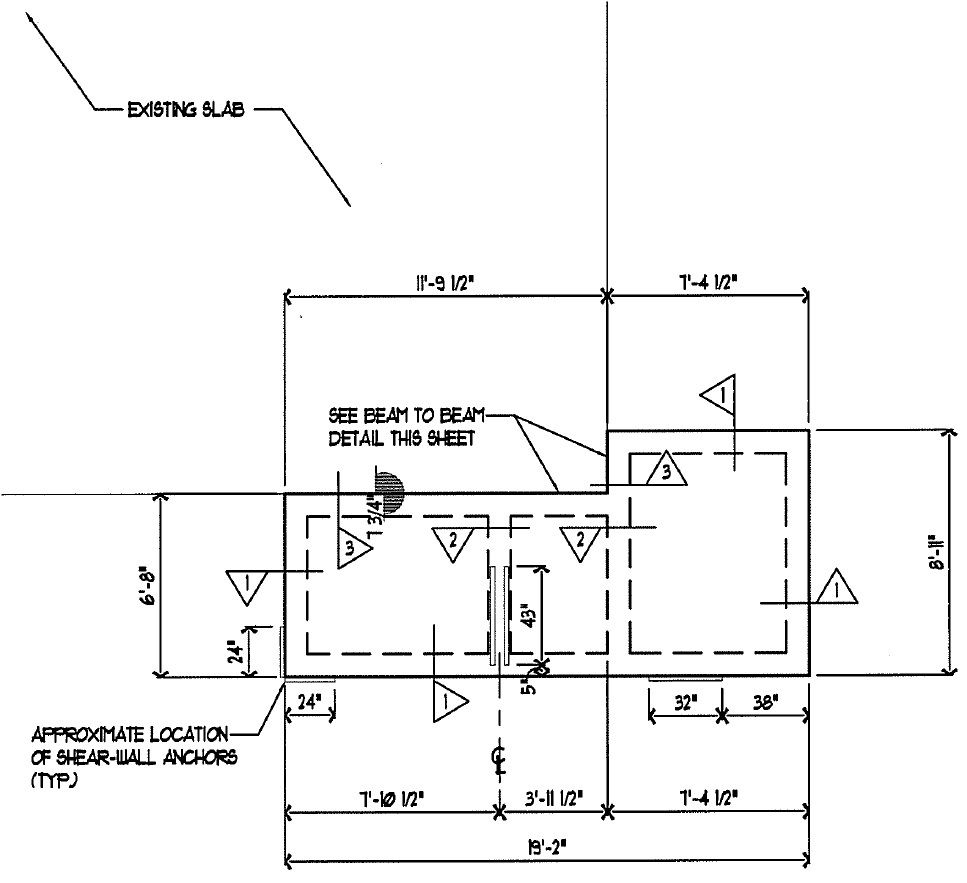

Here is a good diagram I found for pouring the curb without having to put pins in the main slab:

After receiving quotes from very few of the companies that I've called, I think that we're going to try to do it ourselves (15 companies called, 1 provided official quote of $5800, one texted me $2800, one guy ballparked $4000 over the phone. The only two concerns that I have are time and the surface finish. For time, I'll get a trencher; for the surface finish, I'm going to buy a few bags from the box store so that I can practice troweling and water content. Also, it's only 145sf.

For now, I will move some rock fill in as the slab will be elevated in one spot. Anyone have any experience with monolithic pours? With stem walls you pour the walls, compact the fill, then pour the slab. With the monolithic it seems like I should compact a mound in the middle, dig the exterior beams, and then that's it. No room for extra compaction.

27 Aug ’14

Offline

OfflineCorrect. The only concern I have is with the curb but I have decided to fur out about 1/2" beyond the curb so that I have can nail in the gypsum board and so that the gypsum board is not in direct contact with the cement (from what I've read this can lead to water absorption).

Most Users Ever Online: 698

Currently Online:

72 Guest(s)

Currently Browsing this Page:

1 Guest(s)

Top Posters:

easytapper: 2149

DangerDuke: 2030

groinkick: 1667

PorkChopsMmm: 1515

Gravel Road: 1455

Newest Members:

Forum Stats:

Groups: 1

Forums: 12

Topics: 11482

Posts: 58640

Member Stats:

Guest Posters: 2

Members: 19842

Moderators: 0

Admins: 1

Administrators: K

Log In

Log In Home

Home