Don't have time to, wife is starting to get upset with how much time I have been working on this project, crazy it has been almost a year. I was thinking of putting 5/8 Rod through the side of the cabinet so I could lift if needed. My rough calculations it should be about 800 pounds.

Alright @porkchopsmmm , it's been a couple years since I have dumped a bag of cement on the ground, today I dumped 10!

So we removed the mill

poor sad little stand

I removed the middle shelf

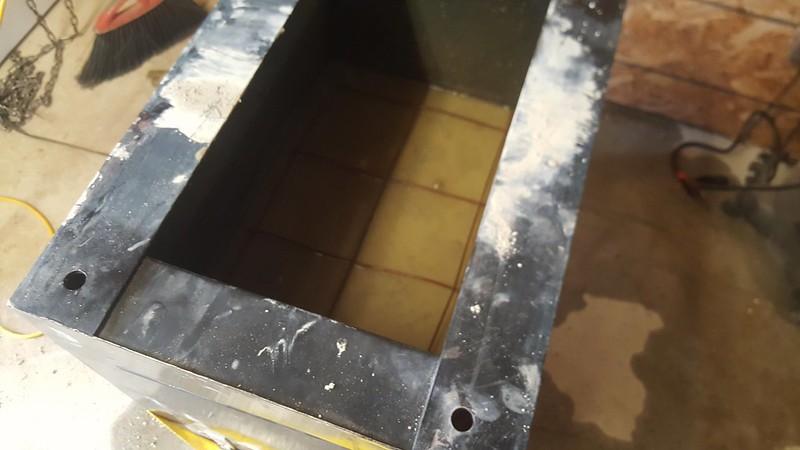

And flipped the stand over, this is an issue, I can't fill it with cement since the bottom has a solid piece

So I broke out the plasma cutter

adios my friend

I grabbed a piece of 6x6 wire

and stuck it in the bottom of the stand

I mixed up some cement and dumped it in

I used a ratchet strap around the stand

and kept adding 6 inches of cement and did another layer of wire

almost to the top

screened it off with a two foot level, need to let it set up before we put the mill back on top

I hope not, should be right around 800 pounds, I was debating putting anchor bolts inside before I poured but if I wanted to move it that would be impossible. I can put steel rods all the way through the square channel at the front and back and lift it with the engine hoist if needed. Going to let it set up some more and then drill the corners and use either leaded lag shields and bolts or expanders to mount the mill, not sure which one I am going to use yet.

got the machine mounted, the back right corner the lead shield pulled out when tightening, I think the top was torqued a little, need to address that in the morning

ordered some mounts for the lathe, need to get it all leveled and then start breaking down the lathe and cleaning it

spent the last couple days getting the lathe leveled, I really hate these sheet metal stands, at some point I need to figure something better out but I threw a couple of lag bolts through the back chip shield and it stiffened it up pretty good

I don't have a machinist level so I used my two foot and I don't think I am going to get it any better than that

today is clean up and organize the shop and then start breaking down the lathe and getting all the cosmoline cleaned off it

27 Aug ’14

Offline

OfflineNice! Leveling for the lathe isn't critical beyond having your coolant flow to a low point (IMO). For the mill, as you've probably noticed in your class, chip control and cleaning can be a pain. We just always used a shop vac when we weren't using any coolant. A good apron is also recommended so that your clothes live longer.

Most Users Ever Online: 698

Currently Online:

24 Guest(s)

Currently Browsing this Page:

1 Guest(s)

Top Posters:

easytapper: 2149

DangerDuke: 2030

groinkick: 1667

PorkChopsMmm: 1515

Gravel Road: 1455

Newest Members:

matt42v054668817

chantalszk

josephinegreenle

Stabrovscort

francisca6319

Forum Stats:

Groups: 1

Forums: 12

Topics: 11478

Posts: 58673

Member Stats:

Guest Posters: 2

Members: 3540

Moderators: 0

Admins: 1

Administrators: K

Register

Register Log In

Log In Home

Home