So I picked up my piece of metal, crazy that this weighs over 100 pounds

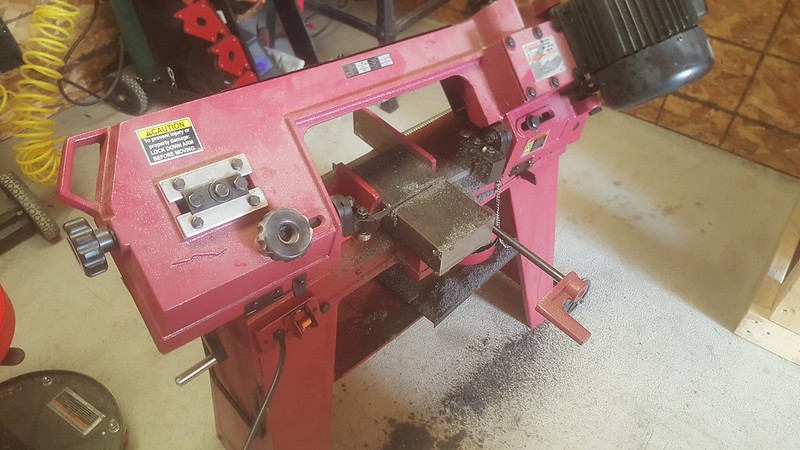

I needed to break it down some so I threw it in the bandsaw

and cut it down again

and again

those 4 inch blocks are 8 pounds each

pork, you had asked earlier what I was going to do with this machine and I had mentioned a few different ideas, one of those is making custom dies for mini hydraulic presses, they have become pretty big over the last several years with diyer's and people that can't afford a 3000 dollar press. We talk a lot about them on the blacksmith thread.

http://thehomesteadi.....mithing-1/

I have been working on one in my spare time over the last month and am getting somewhat closed to finished, one of the biggest questions I have seen on different forums is where to get the dies for the press, this was my question as well. Some fabricate and weld their own up.

I would be sketched out putting 20,000 pounds of pressure on that.

I did find one place that offered dies that would fit with modification, they use to show their prices but no longer do, the last price I saw was 380 dollars for a set.

http://www.anyangrom.....rettyPhoto

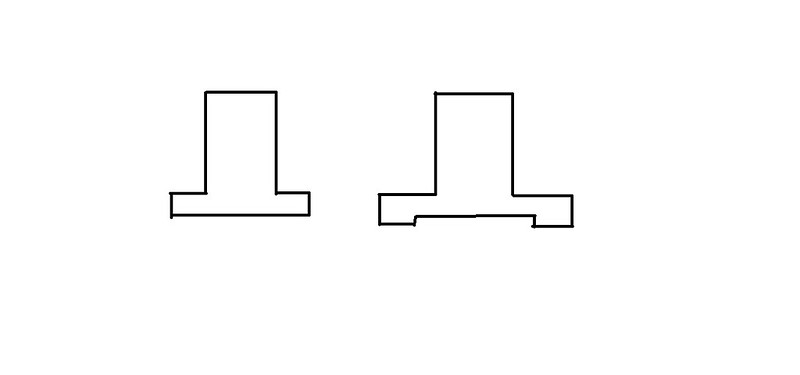

for the diyer there is usually 2 designs, one that sits down into the anvil and bolts retain it

or one that has retaining piece that holds them down

can see it in action here

I am going to mill two different prototypes and offer them for sale, this is not to scale

one that can be retained by bolts on the left, or one that can be retained by being bolted down into the top or the face of the anvil

I think I can do it for a fraction of the 380 dollars.

Need to calculate my feeds and speeds and I'm going to go and try to knock some out.

27 Aug ’14

Offline

OfflineDamn, love the quick release system for swapping them out. Looks like I would need to upgrade compressors. Is that one sitting in your shop large enough?

A note on feeds and spindle speeds with cutting steel - Slower can often be better. We did a lab in college on drilling steel and a lower speed higher feedrate actually cut faster with less energy because it didn't change the phase of the material.

I would also recommend high speed steel end mills as you can always send them off to be re-sharpened and just offset for the tool diameter change, something that the coated ones don't allow. Also for speeds, look into 4 flute vs 2 flute. If you start getting into plastics, two flute no helix helps for making a nice clean edge. Carbide is awesome but of course, pricey. However, it's definitely worth it for things that you use a lot, like center drills.

27 Aug ’14

Offline

OfflineIt happens, if I had to pay my boss back for every piece of equipment that I broke I never would have made any money. The key is noting what happened, I had a student in college (worked PT as a TA in the shop class) who broke three 3/4" end mills trying to plow into a chunk of steel similar to yours. I finally stopped him on the 4th bit and asked him why he thought they were breaking.

Well, my mouse just broke so off to call Microsoft. We'll see if I can still post this without a mouse

I think the big issue was climb milling, it grabbed the piece and ripped it right out of the vice, called smithy up and they are sending me a new one for free. Luckily I had bought a 4 inch off amazon.

I had to grind down the heads on the bolts a little because they were just a hair thick for the slots on the table.

For those wondering what climbing versus conventional is here is a great explanation

The following users say thank you to K for this useful post:

icanreachitMost Users Ever Online: 698

Currently Online:

11 Guest(s)

Currently Browsing this Page:

1 Guest(s)

Top Posters:

easytapper: 2149

DangerDuke: 2030

groinkick: 1667

PorkChopsMmm: 1515

Gravel Road: 1455

Newest Members:

kentduffy8633069

proertTooca

deeeasterling

suelamontagne3

shenna7365

Forum Stats:

Groups: 1

Forums: 12

Topics: 11478

Posts: 58674

Member Stats:

Guest Posters: 2

Members: 3725

Moderators: 0

Admins: 1

Administrators: K

Register

Register Log In

Log In Home

Home