so I was able to sneak away for a couple hours yesterday before easter dinner. First we need to find the center of the edge, so we use an edge finder. It has a tip that offsets and once you get it spinning you slowly move it towards your workpiece until it self aligns. It is important not to go over 1000 rpm so you don't kill yourself.

Once you have it lined up you zero out your axis, but the the tip is .200 so you need to adjust for the .100 radius, so you raise your edge finder and adkust it the .100

Now zero it out again

and you now have your dead center of your edge

do the same on the x axis and you have the center of the corner, which you then use for spacing holes for drilling, etc

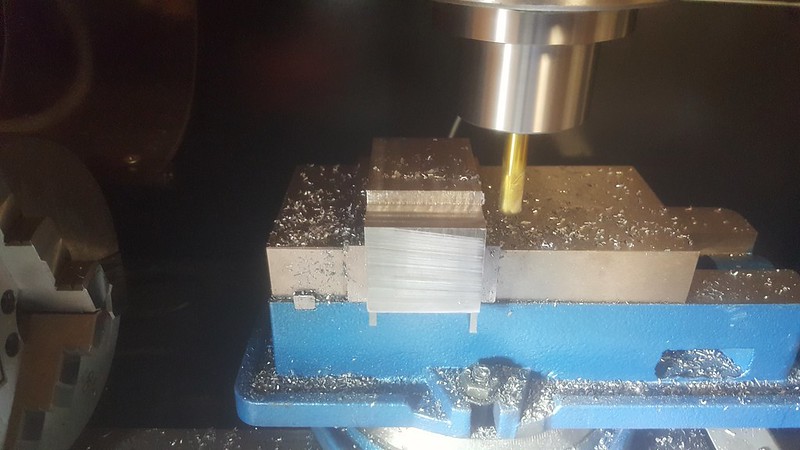

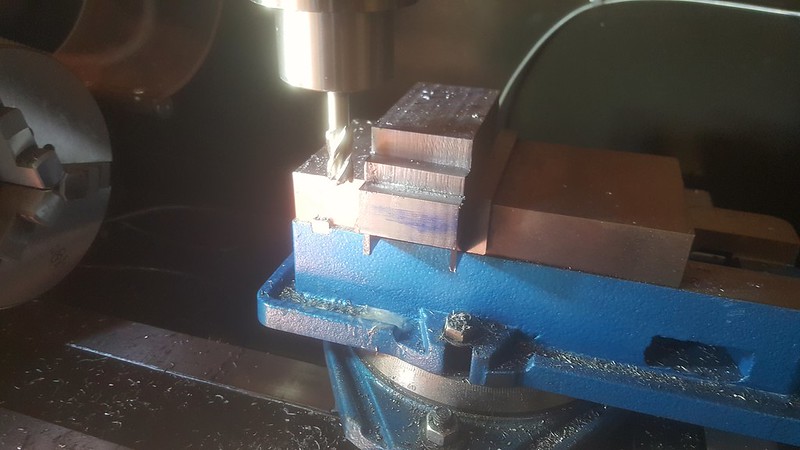

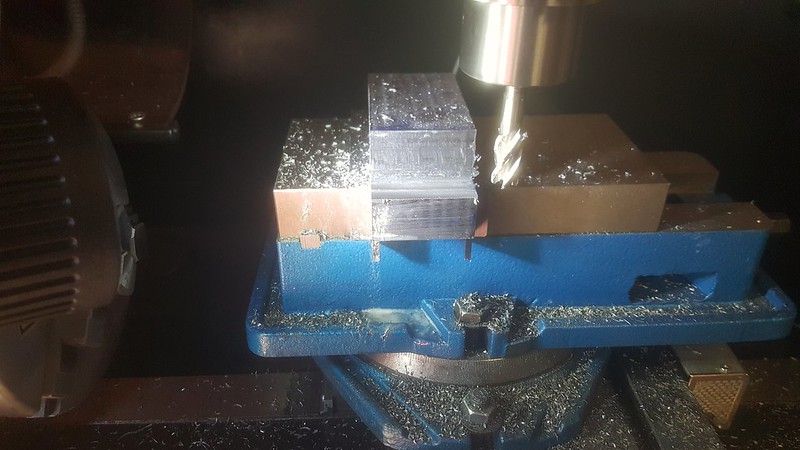

So I started milling out the tabs, slowly working my way through, got a little aggressive with the depth of cut which resulted in the broken end mills above, that is the complaint with a36, you don't know what is in it, it's basically crab structural steel from what I have read, but it is a good learning experience.

so I just took it slow and steady without too many more hiccups

and finished up the one side before dinner

hope to get the other side knocked out today before class

27 Aug ’14

Offline

OfflineYeah, not much you can do to dampen that either. We had machines "walking" around all the time.

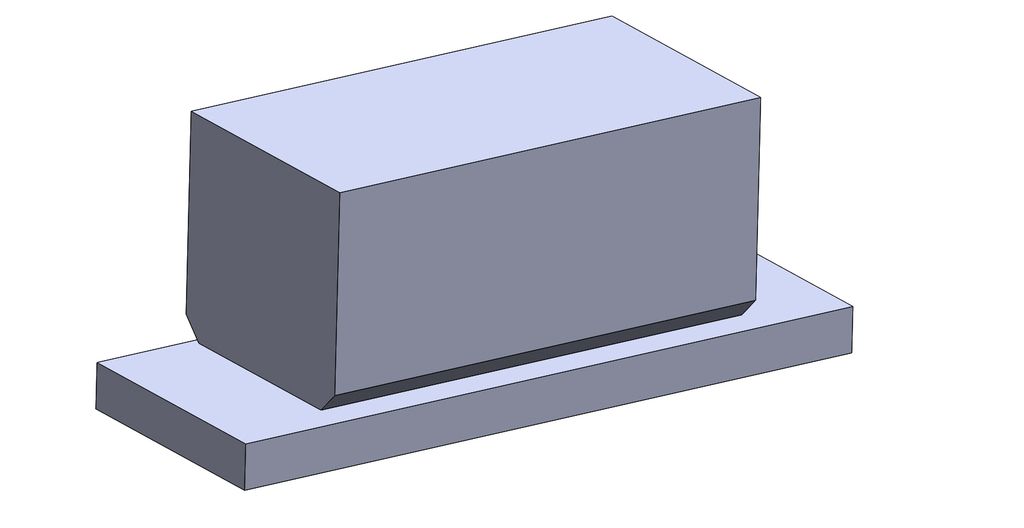

Question on the design: as it sounded like you may want to commercialize it, could you make it out of a smaller block and a plate welded together? This would drastically cut down on your machining time as you would just need to cut the block to length and then square it, no need to cut shoulders. Then just cut a piece of .25 plate to length (ideally find two stock materials that are the same overall width), and then weld them? I added a chamfer just in case you wanted to mill off the bead afterwards.

It wouldn't be as strong in tension or shear but you're using it in compression.

The following users say thank you to icanreachit for this useful post:

KMost Users Ever Online: 698

Currently Online:

19 Guest(s)

Currently Browsing this Page:

1 Guest(s)

Top Posters:

easytapper: 2149

DangerDuke: 2030

groinkick: 1667

PorkChopsMmm: 1515

Gravel Road: 1455

Newest Members:

jeromegarica176

issacsallee

lonchristiansen

quincymccall23

alberthakeighley

Forum Stats:

Groups: 1

Forums: 12

Topics: 11479

Posts: 58674

Member Stats:

Guest Posters: 2

Members: 3578

Moderators: 0

Admins: 1

Administrators: K

Register

Register Log In

Log In Home

Home