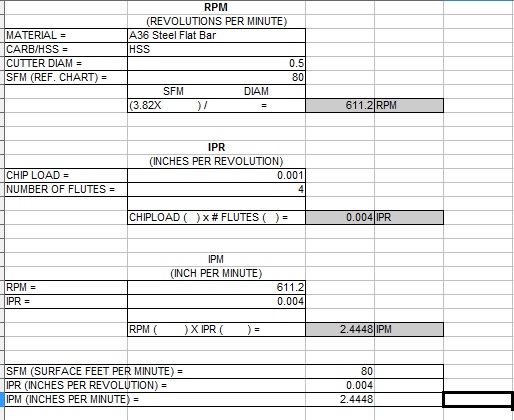

agreed, so I did another calculation, my charts don't have A36 on them but most of what I am reading online is that it is a cross between machine steel and mild steel, so I took the high range of the machine which is the low range for the mild, I will test it with the lowest chip load and adjust up to the max of .003 if everything goes well which will increase my IPM to 7.3344

27 Aug ’14

Offline

OfflineI won't lie, I didn't start using charts until I got into CNC. Prior to that it was always based off of feedback from vibration through my hands and the noise of the cut from my ears. Kind of like driving a manual. Your first clutch never lasts as long as the subsequent. With that said, I wish I had used the charts earlier on.

we spent basically the first two classes going over that kind of stuff, the instructor gave us worksheets exactly like the one above so we could manually calculate them, I created a spreadsheet with the calculations built in so all I have to do is pop in the cutter diam, SFM, chip load and flutes and it will pop out my numbers for me, he does a lot of high end milling for his job and says he still calculates it on paper and keeps a copy on hand if there is ever an issue or he needs a quick reference, I figured it was a good practice to utilize

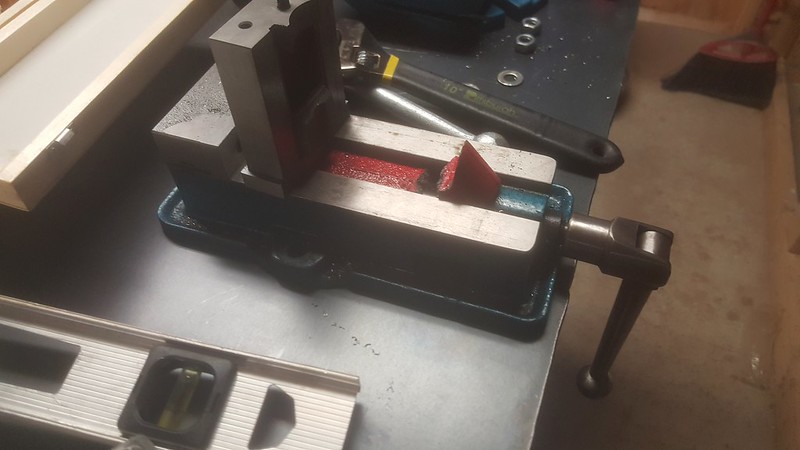

so another part of the issue the other night was set up, too high plus wrong orientation and climb milling threw that piece right out of the vice

hey, I'm still learning, we have only practiced on aluminum!

RIP little vice

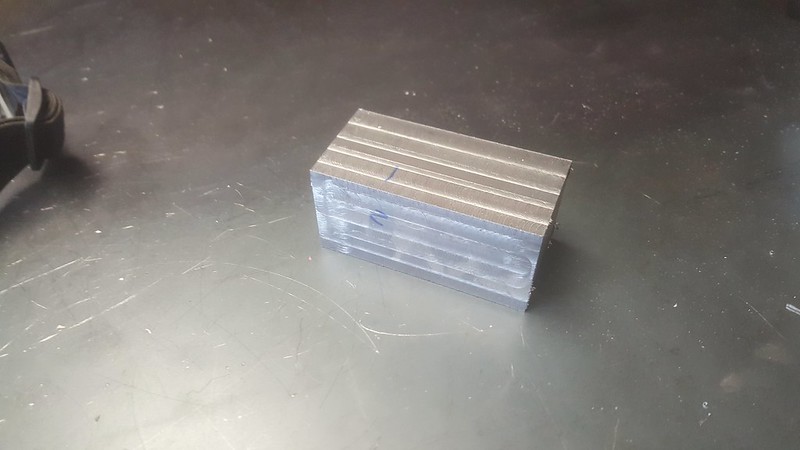

So I was rethinking my design and decided that a 2x2x4 would be the perfect size to mill from, so I cut down the A36 in my bandsaw

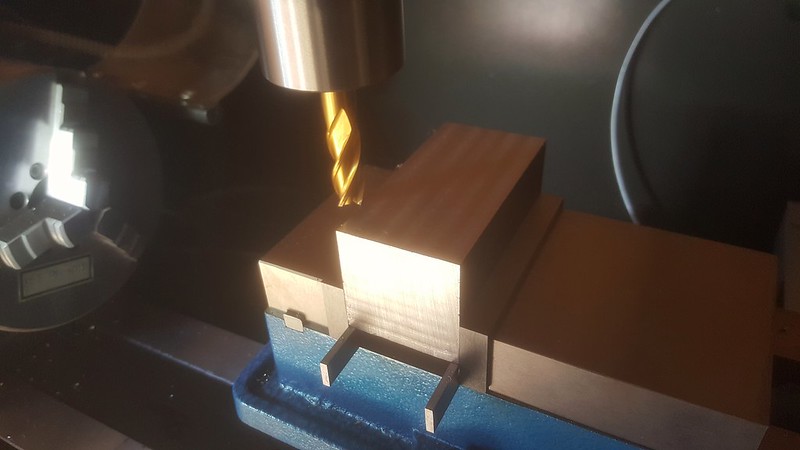

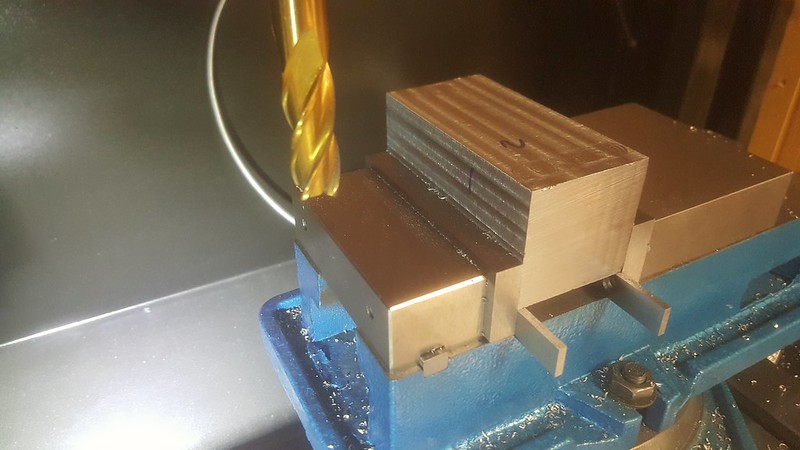

I followed the feeds and speeds calculation I posted and cut through the outer shell fine

now we have to square the piece, since we have one flat surface we turn that towards the face of the vice, and mill the top, so we have surface 1 and 2

we then turn face 2 towards the vice with 1 down and mill surface 3

we then finish off with surface 4

now we have a square piece of stock and it is time to make a prototype

27 Aug ’14

Offline

OfflineGreat work! Can't wait to see the final results! Are you planning to weld a tab on for the slot or mill it down so that you've got shoulders for the slot?

For smaller pieces you may look at a small tumbler in the future as that'll take care of all of your burs and give you a nice uniform finish. I personally love the freshly machined look so I try to just trim burs.

It's definitely a learning process. In a few months you'll be making things fancier than this:

The following users say thank you to icanreachit for this useful post:

KMost Users Ever Online: 698

Currently Online:

33 Guest(s)

Currently Browsing this Page:

1 Guest(s)

Top Posters:

easytapper: 2149

DangerDuke: 2030

groinkick: 1667

PorkChopsMmm: 1515

Gravel Road: 1455

Newest Members:

Forum Stats:

Groups: 1

Forums: 12

Topics: 11482

Posts: 58640

Member Stats:

Guest Posters: 2

Members: 19842

Moderators: 0

Admins: 1

Administrators: K

Log In

Log In Home

Home